Businesses frequently encounter challenges when managing patchwork supply chains for plastic product development. They find themselves coordinating between separate graphic designers, packaging manufacturers, and fulfillment services. This often leads to project management complexity, increased costs, and inconsistent quality standards across the production lifecycle.

A consumer chemical products manufacturer required custom plastic containers for its products. Their existing process involved sourcing these containers from one vendor, coordinating graphic design with another, then managing separate packaging production and final packing operations.

This fragmented system created logistical challenges and slowed their time to market. Their search for a streamlined, single-source solution for both their plastic containers and downstream needs led them to explore American Plastic’s injection molding services that included assembly, packaging, and drop ship capabilities.

The Challenges of Juggling Multiple Vendors

A prominent spa and pool care product manufacturer struggled with their three-vendor approach to plastic treatment container production. Their divided system between independent graphic designers, packaging producers, and fulfillment centers created persistent communication breakdowns. Quality inconsistencies emerged at each transition point, while production delays became increasingly common and costly to resolve.

The manufacturer required precise component assembly and packaging for their pool treatment products. This proved extremely challenging. Label placement inconsistencies and packaging quality issues frequently occurred between handoffs from one vendor to another. Major retail relationships with home improvement chains became threatened as delivery deadlines were missed.

The fragmented vendor approach created four critical business challenges:

- Regular delays: Coordinating a plastics molder with separate design and packaging vendors often led to misaligned schedules. This directly impacted their ability to meet market demand and launch promotional campaigns effectively.

- Inconsistent quality: Variations in plastic container quality or a lack of cohesion between the primary container and secondary packaging resulted in inconsistent final presentation. This risked damaging brand perception and eroding customer trust.

- Increased costs: Managing separate contracts for plastic molding, design, packaging materials, and fulfillment created significant administrative overhead. These indirect costs, coupled with potential rework, substantially inflated overall project expenditure.

- Wasted resources: Valuable internal employee hours were diverted to managing the complexities of this multi-vendor network. This significant misallocation of skilled resources hindered strategic initiatives within the company.

Complete Solution With Single Provider Integration

American Plastics delivered a comprehensive single-source solution by unifying all production stages under one roof:

Streamlined Manufacturing Process

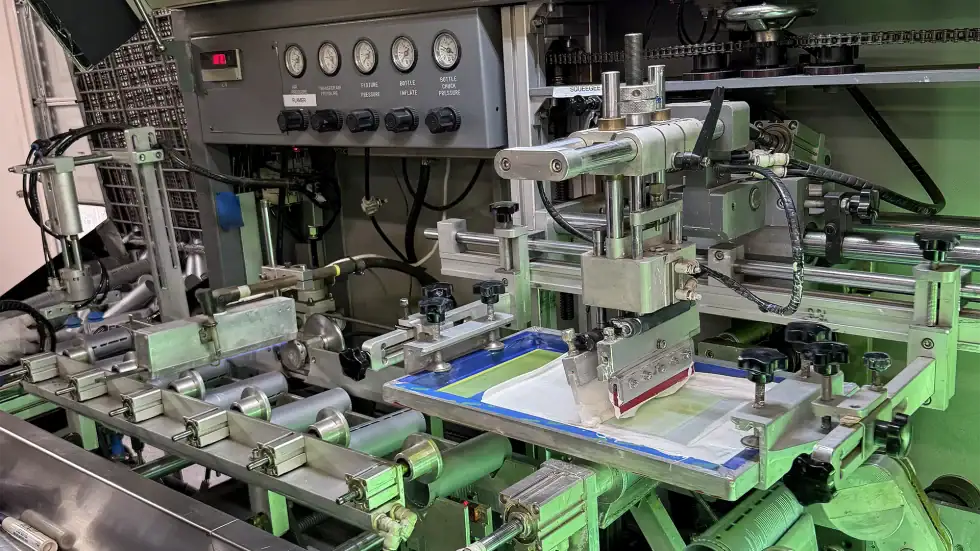

Ultrasonic welding technology was utilized to create secure, tamper-evident seals without chemical-reactive adhesives. Dedicated project managers and a robust quality control management system verified consistent specifications across all production phases. The implementation transformed a previously complex multi-vendor workflow into a streamlined process with centralized accountability.

Advanced Technology Systems

In-house designers collaborated directly with the client on packaging that balanced visual appeal with functional requirements for chemical storage. Digital proofing systems eliminated traditional approval delays between the design and production phases.

Engineers developed custom tooling specifically designed for this product line to ensure optimal material usage and consistency. American Plastic’s specialized filling facility maintained precise measurements for pool treatment products while meeting stringent safety regulations for chemical packaging.

Precision Testing and Quality Assurance

American Plastics reinforced product reliability through advanced testing protocols and real-time data tracking. Proprietary software provided continuous visibility into production status and supported data-driven decision-making across departments. A dedicated quality control team operated within a full ISO 9001-certified environment, utilizing sophisticated metrology and material analysis equipment to ensure compliance with performance standards.

Unified Production Delivers Quantifiable Results

The consolidated production approach reduced the client’s time-to-market by 37% compared to previous multi-vendor methods. Manufacturing expenses decreased as American Plastics eliminated redundant handling, cross-facility transportation, and excessive quality checkpoints. The client gained renewed confidence in their supply chain reliability while maintaining consistent product availability for retail partners.

“Partnering with American Plastics streamlined our supply chain,” said the Vice President. “Their end-to-end solution eliminated vendor chaos and gave us back control over quality and timelines.”

Product rejection rates decreased dramatically from 4.2% to under 0.5% under American Plastic’s comprehensive quality protocols. Distribution networks expanded to include major retailers like Lowe’s and Home Depot through American Plastic’s efficient drop shipping capabilities.

Direct fulfillment to distribution centers nationwide strengthened the client’s market position substantially. Improved service reliability and consistent product quality established them as a preferred vendor within the competitive spa and pool care market.

Partner with American Plastics for Start-to-Finish Production Jobs

At American Plastics, we transform fragmented production processes into cohesive workflows, delivering superior market results. Our comprehensive capabilities span design, injection molding, assembly, filling, and fulfillment without requiring multiple vendor relationships. Click below to learn more and speak with one of our expert team members.