Many manufacturers struggle to find injection molders that can maintain consistent quality standards or provide in-house quality inspection procedures that meet specific industry requirements. Quality issues that arise from a lack of thorough inspection lead to production delays and costly rework that impact project timelines or budgets.

At American Plastics, we have an in-house ISO 9001-certified quality-control department that eliminates these concerns through rigorous testing and inspection. Our advanced equipment and experienced technicians help ensure every plastic injection-molded part meets specifications the first time.

Read on to learn more about how our injection molded parts inspection services deliver the precision parts your business requires.

What Are In-House Quality Control Services for Injection Molding?

In-house quality control involves comprehensive inspection processes throughout the manufacturing cycle. These processes include dimensional verification, visual inspections, and performance testing to ensure parts meet specifications. Proper documentation and record-keeping track every aspect of production for traceability and compliance purposes.

There are several benefits to working with an injection molding company with in-house QC in Arizona:

- Faster Issue Resolution: Problems can be identified and corrected immediately without shipping parts to external testing facilities. This rapid response prevents small issues from becoming costly production delays.

- Direct Communication: Your team can speak directly with the technicians performing the inspections and testing. This eliminates miscommunication that often occurs when working through third-party labs.

- Cost Savings: Eliminating external lab fees and shipping costs reduces your overall project expenses. You also avoid the markup that many molders add when outsourcing testing services.

- Consistent Standards: The same trained personnel use identical procedures for every batch of parts. This consistency ensures reliable results across multiple production runs.

- Customized Testing: The QC team can develop specific inspection protocols tailored to your unique requirements. Standard external labs often use generic testing procedures that may miss critical specifications.

Injection Molding with Quality Inspection in Arizona

American Plastics is a plastic injection molder with in-house quality control (QC). Our facility handles comprehensive testing requirements, including structural testing, fatigue testing, heat reversion testing, pressure burst testing, and crush testing.

High-performance projects requiring tight tolerances are analyzed using advanced coordinate measuring equipment that takes precise measurements along multiple axes. For all inspection needs not covered by American Plastics, companies can elect to work with a provider specializing in dimensional inspection of plastic parts.

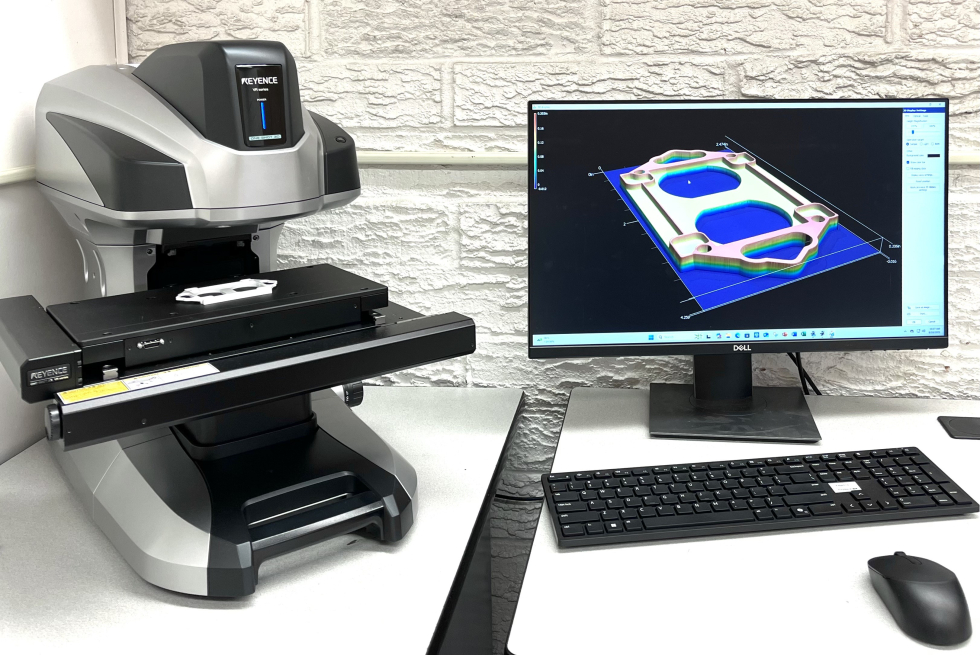

Our new Keyence 3-D Optical Profilometer provides state-of-the-art advancements to our QC department. This machine allows us to create programs of critical dimensions and apply those to samples taken on a customer-approved schedule in a speedy manner. The profilometer measures critical dimensions and can compare molded parts to each other and to the CAD model.

Every part we manufacture goes through a comprehensive three-tiered quality control system to ensure 100% precision and accuracy:

Tier 1 Quality Control

Our team produces first article parts and creates comprehensive inspection reports for customer review and approval. These approved reports become the dimensional benchmark for all future production runs. Additional capability studies are performed for projects requiring extremely tight tolerances.

Tier 2 Quality Control

Customer specifications for appearance, functionality, fit, tolerances, and testing requirements are used to create a Customized Detailed Inspection Plan. This plan incorporates routine testing protocols such as heat reversions, crush testing, and burst pressure testing. Both destructive and non-destructive testing methods ensure the integrity of every manufactured part.

Tier 3 Quality Control

The Customized Detailed Inspection Plan guides all in-process manufacturing checks and documentation procedures. Every team member follows uniform protocols for dimensional inspections, visual checks, and testing procedures. This system also covers final inspections, certifications, and any required packaging or labeling operations.

Our Value-Add Services

In addition to injection molding, design & tooling, we offer the following additional services that maximize efficiency and provide significant value by keeping everything under one roof:

In-House Printing, Filling, and Labeling

Our facility provides complete printing and labeling services, including screen printing, pad printing, heat transfer labeling, and hot stamping. We handle challenging materials and irregular surfaces while accurately reproducing corporate logos, product numbers, and custom artwork.

Product Filing, Packaging, and Drop Shipping

We offer specialized filling and packaging services for various industries, including measured dosage filling for pool and spa treatment products. Our team also handles drop shipping directly to distribution warehouses to save you time and reduce logistics costs.

Ultrasonic Welding and Final Assembly

Ultrasonic welding joins multiple plastic components using high-frequency vibrations instead of adhesives or mechanical fasteners. This clean and precise technology is ideal for automotive, electronic, and medical applications that require strong permanent bonds.

How Certain Plastic Resins Can Impact Product Quality

Choosing the right plastic resin has a direct correlation to the final part’s performance, durability, and appearance. Different materials can provide specific mechanical and chemical properties that determine whether parts will meet your project requirements. This decision is critical for tightly regulated industries like plastic-injected molded parts for medical applications or high-performance environments.

Our quality control process begins with expertise across a diverse range of commodity and engineering-grade plastics, including:

- ABS (Acrylonitrile Butadiene Styrene): This versatile thermoplastic provides a high-quality, glossy surface finish and excellent impact strength, ensuring products are both aesthetically pleasing and durable enough to withstand physical stress.

- Polycarbonate (PC): Known for its superior impact resistance and optical clarity, polycarbonate is essential for producing high-quality transparent parts that require extreme toughness and stability.

- Nylon (PA): We utilize nylon for applications demanding high mechanical strength and resistance to wear and chemicals, resulting in quality parts that perform reliably in harsh operating environments.

- Polypropylene (PP): Valued for its chemical resistance and fatigue strength, polypropylene is key to creating high-quality living hinges and parts that must endure repeated motion without failure.

- Acetal (POM): This material is selected for its low friction and high stiffness, which is critical for producing quality precision parts like gears and bearings that require dimensional stability and smooth operation.

Quality Control Services for Injection Molded Parts

Choosing a vendor that offers plastic injection molding with dimensional inspection ensures your projects meet exact specifications without delays or costly rework. This integrated approach eliminates external testing delays and maintains tighter control over production schedules.

At American Plastics, we’ve integrated thorough and rigid inspection protocols and procedures for all of our injection-molded parts. Our growing collection of advanced equipment and rigorous inspection procedures guarantees precision and maximum efficiency for all projects. The comprehensive manufacturing and testing approach offered by the experts at American Plastics delivers the reliability and consistency your business demands.

Click below for a quote and to learn more about how our in-house quality control capabilities can streamline your next injection molding project.