Companies searching for thermoplastic injection molding services often encounter delays due to outsourced tooling, inconsistent quality controls, or reliance on multiple vendors for assembly and packaging. These gaps can extend lead times and complicate production for industrial, medical, and consumer products.

At American Plastics, we manufacture thermoplastic injection molded parts in-house using ISO 9001-certified processes at our facility in Glendale, Arizona. We handle mold design, plastic molding, and final assembly, including printing, labeling, and packaging.

Read on to learn more about how thermoplastic injection molding works and where it delivers the best performance.

The 5-Step Thermoplastic Injection Molding Cycle

Thermoplastic injection molding is a manufacturing process that produces parts from plastic materials. It begins with melting thermoplastic polymers and injecting them into a specially designed mold. The material then cools and solidifies inside the mold to create the final component.

The entire process operates as a continuous cycle. A full manufacturing cycle is completed in a matter of seconds. This high-speed repetition makes the process a primary method for mass-producing identical components.

The manufacturing cycle includes the following stages:

- Clamping: A hydraulic press holds the two halves of the mold together under high pressure. This force counteracts the injection pressure and prevents the mold from opening during the cycle.

- Injection: A reciprocating screw melts the plastic pellets and injects the molten material into the mold. The screw forces the material forward until the mold cavity is filled.

- Cooling: The molten plastic solidifies within the mold. Internal channels circulate fluid through the mold to regulate the temperature and control the cooling rate.

- Ejection: The mold opens after the part has sufficiently cooled. A system of ejector pins then pushes the finished component out of the mold cavity.

- Finishing: The newly molded part is removed from the machine for inspection. Any excess material from the runner, gate, or flashing is trimmed from the final component.

Arizona Thermoplastic Injection Molding Company

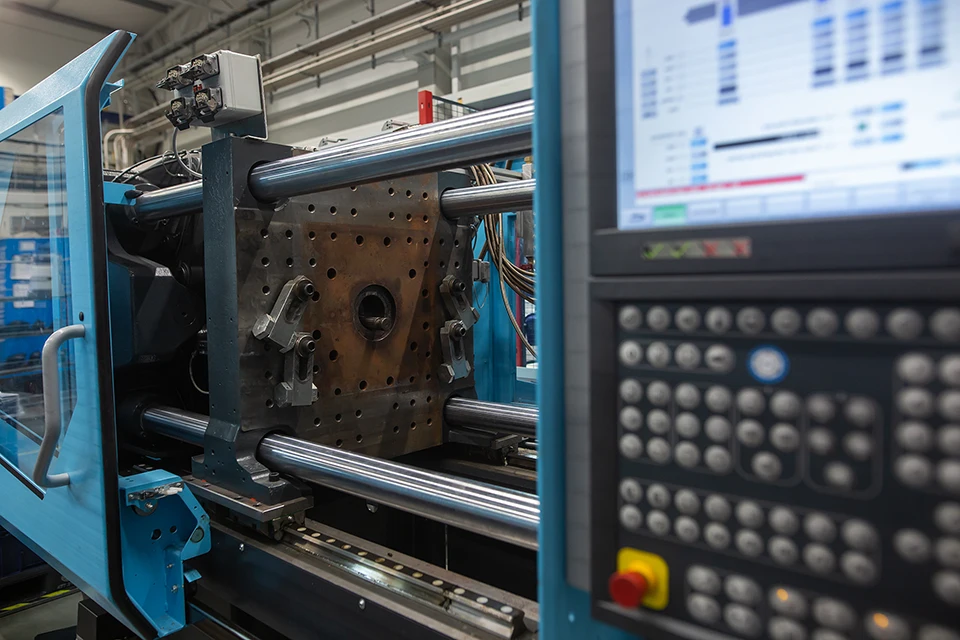

American Plastics provides thermoplastic injection molding services from our facility in Arizona. We have an ISO 9001 certification and operate a collection of modern equipment to meet industry specifications. Our capabilities include thirteen injection presses with clamping forces from 55 to 400 tons.

The machinery in our facility accommodates a wide range of part sizes and shot weights. We work with various materials, from common resins like polyethylene and polystyrene to engineering-grade polymers such as nylon and polycarbonate. This includes frequent use of ABS, Acetal, HDPE, and other specialized compounds.

Our Value Added Services

American Plastics also provides several in-house services to finish components after the primary molding cycle. Available value-added services include:

- Component Assembly and Finishing: Ultrasonic welding joins separate plastic components into a single product. Our finishing capabilities include the application of custom graphics and information through printing and labeling services.

- Mold Design and Tooling: Our design and tooling services utilize local partners to produce tight-tolerance injection molds. These partners use CNC machining for complex designs, and the finished molds are treated to improve production efficiency.

- Product Assembly and Fulfillment: We handle final product assembly entirely in-house. Our services include measured filling, hot stamping, pad printing, and heat transfer labeling, along with order fulfillment and drop shipping to distribution centers.

How Automation Drives Production Efficiency

Thermoplastic injection molding provides high production efficiency. The automated nature of the process and rapid cycle times enable large quantities of parts to be manufactured quickly. This high-volume output significantly lowers the cost of each piece.

Using thermoplastics for injection molding allows for the creation of complex part designs. For example, tight dimensional tolerances can be maintained across high-volume production runs, ensuring part consistency. A wide selection of available polymers also enables material properties to be matched to a component’s specific application.

Industries We Work With

Many commercial industries depend on thermoplastic injection molding for component production. The process is ideal for manufacturing large volumes of identical parts that require high precision.

- Automotive: The automotive industry uses the process to produce parts like interior dashboards, trim components, and exterior bumpers.

- Medical: Medical device manufacturing relies on the method for creating sterile products, including surgical instruments, diagnostic components, and equipment housings.

- Consumer Goods: Consumer goods producers utilize injection molding for manufacturing items such as electronic enclosures, toy components, and household appliance parts.

- Electronics: The electronics sector employs the technique to create intricate parts like connectors, switches, and protective casings for devices.

- Construction: Construction applications include the mass production of pipe fittings, electrical boxes, fasteners, and various building hardware.

Material Selection Guide

A wide range of thermoplastic materials is available for injection molding. Polypropylene offers excellent chemical resistance and is used in packaging and automotive components. Polyethylene provides high impact strength and is frequently used for consumer products and containers.

Engineering-grade resins deliver enhanced mechanical properties for more demanding applications. Acrylonitrile Butadiene Styrene, or ABS, is a rigid material known for its strength and quality surface finish. Polycarbonate provides superior impact resistance and optical clarity for applications like lenses and protective housings.

Partner With American Plastics for Expert Thermosplastic Injection Molding Services

Thermoplastic injection molding delivers exceptional efficiency and precision for producing high-volume plastic components across diverse industries. This automated manufacturing technique enables rapid cycle times while accommodating complex designs and various polymer materials to meet specific application requirements.

At American Plastics, our ISO 9001-certified facility in Glendale, Arizona, combines advanced equipment with extensive material knowledge to achieve superior outcomes. We use a comprehensive in-house approach to streamline production timelines for critical components.

Click below to get a quote and learn more about our injection molding services.